What is Vernier Caliper?

Vernier Calipers are widely used in automotive industry for measurement of various parts. The old caliper looks like a tomahawk with the scale dawn its length. A measuring instrument consisting of an L-shaped frame with a linear scale along its longer arm and an L-shaped sliding attachment with a vernier, used to read directly the dimension of an object represented by the separation between the inner or outer edges of the two shorter arms.

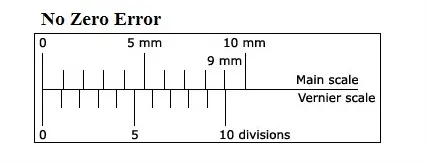

Likewise micrometer screw gauge, the Vernier Caliper is used to take the measurement that are accurate to within 0.001 of an inch or 0 .02 of a millimeter or in other words its used to make very accurate measurements which cannot be accurately measured from a meter scale. The Vernier Caliper is a precision instrument that can be used to measure internal and external diameters of small tubes, depth of given vessels, diameter of thick wires, etc. It has two scales, one is the vernier scale and the other is the main scale. The vernier scale is also called the sliding scale as it slides on the main scale, which is fixed.